Clean cable cuts are not just about appearance. They directly affect installation speed, system strength, and long-term durability. In cable railing projects, frayed ends slow down hardware installation, reduce tension accuracy, and create safety concerns.

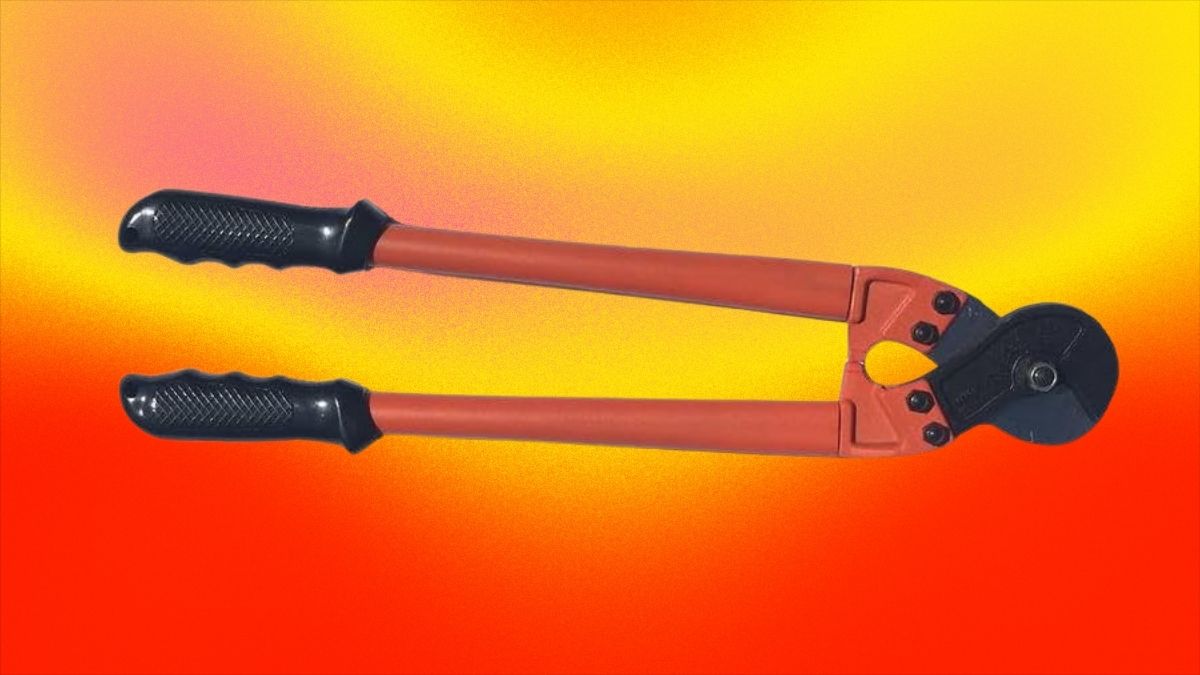

VistaView CableTec’s hardened steel cable cutters with tapered jaws are designed specifically for stainless and galvanized cable work. Built to handle common railing diameters from 1/16″ up to 1/4″, these cutters focus on precision, durability, and installer efficiency.

The Engineering Behind VistaView CableTec Cable Cutters

Before looking at performance, it helps to understand how the tool is built and why those choices matter on the jobsite.

Hardened Steel Construction

The cutters are made from heat-treated hardened steel. This process increases tensile strength and wear resistance, which is critical when cutting stainless steel cable repeatedly.

The result is consistent cutting performance over time, even after hundreds of cuts.

Tapered Jaw Design

The rounded, tapered jaws are the defining feature. Instead of spreading cable strands outward, the jaws compress them evenly during the cut.

This design:

- Produces cleaner, square cuts

- Reduces strand separation and fraying

- Eliminates the need to tape cables before cutting

For installers, this saves time and reduces rework.

Optimized Length and Weight

At 18 inches long and approximately 3.5 pounds, the cutters balance leverage and control. The length provides sufficient mechanical advantage for cutting 1/4″ cable without making the tool awkward in tight spaces.

This balance helps reduce hand strain during repetitive cutting.

Handle and Visibility Design

The stainless steel handles resist corrosion in outdoor and coastal environments. The high-visibility orange finish improves tool visibility on busy jobsites and reduces the risk of misplaced tools.

Cutting Capacity and Performance

VistaView CableTec cutters are calibrated for common cable railing sizes without adjustment.

Supported Cable Diameters

- 1/16″ (1.59 mm)

- 3/32″ (2.38 mm)

- 1/8″ (3.18 mm)

- 5/32″ (3.97 mm)

- 3/16″ (4.76 mm)

- 1/4″ (6.35 mm)

Stainless vs. Galvanized Cable

Stainless steel cable requires more cutting force due to its higher tensile strength and work-hardening properties. The cutter geometry accounts for this difference, maintaining clean cuts across both materials.

Cut Quality

Testing shows clean, square cuts on 1/4″ stainless cable without pre-taping. Blade alignment and jaw compression prevent strand flare, allowing cables to seat properly into fittings.

Cable Railing Installation Benefits

Precision cutting directly affects system performance and final appearance.

Workflow Integration

These cutters are used at two key stages:

- Initial sizing before installation

- Final trimming after tensioning

At both points, cables are ready for hardware immediately after cutting.

Aesthetic and Safety Impact

Clean cuts:

- Improve hardware fit

- Reduce exposed sharp strands

- Enhance finished appearance

- Help maintain system strength

This is especially important for code-compliant railing systems where tension accuracy matters.

Comparison with Other Cutting Methods

| Method | Common Issues |

| Bolt cutters | Crushed and frayed ends |

| Angle grinders | Heat damage, sparks, safety risks |

| Hacksaws | Slow cuts, uneven results |

| Cable cutters | Clean cuts with minimal effort |

Ergonomics and Safety

The tool is designed for controlled, two-handed operation.

- Handle spacing supports different hand sizes

- Textured grips maintain traction in wet or dusty conditions

- Longer handles reduce required grip force

Compared to grinders or saws, these cutters introduce fewer safety risks. There is no heat, no sparks, and no exposed rotating blades.

Maintenance and Tool Longevity

Basic care helps preserve cutting performance.

Recommended practices:

- Clean jaws after use

- Oil the pivot point monthly

- Wipe down after moisture exposure

- Store in the closed position

Routine inspection should focus on the cutting edges and pivot mechanism.

Cost and Long-Term Value

While the initial cost is higher than general-purpose tools, the value becomes clear over time.

Key factors include:

- Reduced installation time

- Fewer failed cuts

- Longer tool lifespan

- Less fatigue during repetitive work

For installers handling multiple railing projects per year, the tool often pays for itself quickly.

A Reliable Tool for Precision Cable Work

VistaView CableTec hardened steel cable cutters are built for installers who need consistent, professional results. The tapered jaw design minimizes fraying, while the hardened steel construction supports long-term use on stainless and galvanized cable.

For anyone working regularly with 3/16″ to 1/4″ cable, purpose-built cutters like these simplify installation and improve final results. Clean cuts make the rest of the job easier—and safer—from start to finish.