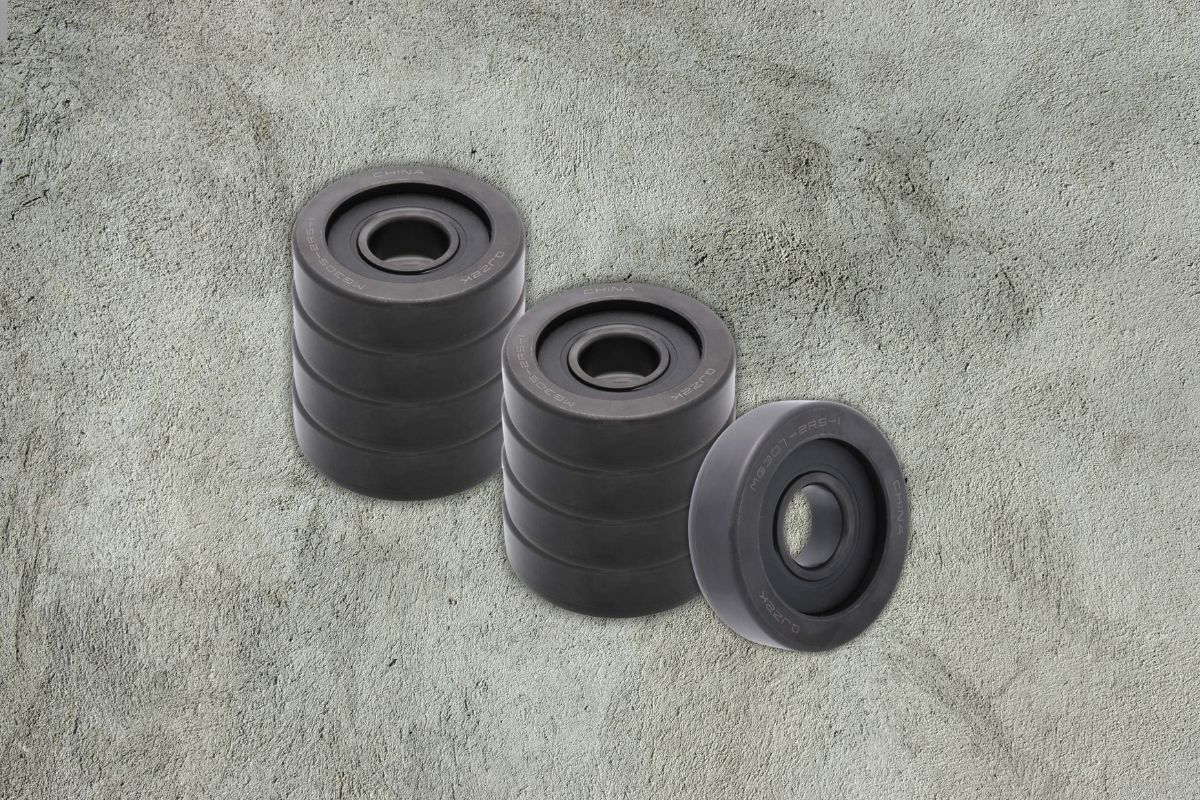

Forklift maintenance can make or break your warehouse operations. I recently discovered that equipment downtime costs industrial facilities an average of $22,000 per minute – a staggering figure that highlights the importance of quality replacement parts. The [8-Pack] MG307-2RS-1 Mast Guide Ball Bearing by QJZ represents the intersection of precision engineering and operational reliability. With its double rubber seal design and impressive load ratings, this bearing pack offers a comprehensive solution for maintaining forklift mast systems. Whether you’re a maintenance supervisor or procurement specialist, understanding the specifications and benefits of these specialized bearings can significantly impact your equipment’s performance and longevity.

Technical Specifications and Compatibility

The MG307-2RS-1 Mast Guide Ball Bearing stands as a precise engineering solution designed specifically for forklift applications. These bearings feature exact dimensions that make them ideal for industrial machinery: 35mm inner diameter, 101.346mm outer diameter, and 28.575mm width. This precision ensures proper fit and function in demanding forklift operations.

The load capacity specifications demonstrate the robust nature of these bearings. With a dynamic load rating of 33.40 kN and a static load rating of 19.2 kN, these components are built to handle significant operational stress. The double rubber seal (2RS) design provides crucial protection against environmental contaminants that could otherwise compromise performance.

Additional technical measurements include:

- C-dimension: 21.000 mm

- r-dimension: 9.525 mm

- E-dimension: 4.550 mm

One significant advantage of the MG307-2RS-1 bearings is their broad compatibility. They can be interchanged with numerous part numbers, including MG307FFH, 307SZZ10, BB2005-2, 99607DTY1Z8, X376RS, MG307RS-1, MG307.2RS-1, and MG307SZZ-10. This versatility simplifies inventory management and parts sourcing.

QJZ, the manufacturer, has established a reputation for industrial-grade quality. Their production standards ensure consistent performance across all bearing units in this 8-pack configuration.

Applications in Forklift Mast Systems

Mast guide ball bearings serve a critical function in forklift operations. As primary components in vertical mast assemblies, these bearings ensure smooth lifting operations by maintaining precise movement paths. Their proper functioning directly affects load stability during material handling tasks.

These bearings are essential for maintaining accurate vertical movement in telescopic mast systems. The precision engineering of the MG307-2RS-1 allows for reliable operation when raising and lowering heavy loads. This becomes particularly important when handling fragile materials or when precise positioning is required.

The standardized dimensions of these bearings make them suitable for various forklift brands and models. This universal application capability increases their utility across diverse warehouse and industrial environments.

Beyond basic functionality, these bearings play a vital role in preventing mast wobble—a significant safety consideration for forklift operators. Stable mast operation reduces the risk of load shifting and potential accidents. Furthermore, proper load distribution through quality bearings contributes to an extended forklift lifespan by reducing stress on other components of the lifting system.

Performance Benefits and Durability Features

The double rubber seal design of the MG307-2RS-1 bearings provides multiple performance advantages. This sealing system effectively prevents dust, debris, and moisture infiltration, common challenges in warehouse environments. By keeping contaminants out, the bearings maintain their internal precision and lubrication integrity.

Precision engineering distinguishes these bearings from lower-quality alternatives. The exacting manufacturing standards ensure consistent performance under heavy loads, reducing the risk of operational failure. This precision also contributes to reduced friction and heat generation during continuous operation, factors that can significantly impact bearing lifespan.

From a maintenance perspective, these high-quality bearings minimize required service frequency and extend intervals between replacements. This translates to reduced downtime and lower maintenance costs over the operational life of the forklift.

The MG307-2RS-1 bearings help maintain accurate load positioning during lifting operations—a critical factor in warehouses with high shelving or precise stacking requirements. Their engineering accommodates the demanding conditions typical of warehouse environments, including temperature variations, dust exposure, and continuous operation.

An often overlooked benefit is the contribution to smoother overall forklift operation. Quality bearings reduce vibration and operational noise while potentially lowering energy consumption through reduced friction and more efficient movement.

Value Proposition of the 8-Pack Configuration

The 8-pack configuration of the MG307-2RS-1 bearings offers substantial economic advantages compared to individual bearing purchases. At $258.70 for the set, the per-unit cost provides significant savings over single-unit pricing, especially when considering the eventual need for replacement of multiple bearings.

Having an inventory of replacement parts on hand delivers operational benefits by ensuring immediate availability during scheduled maintenance cycles. This proactive approach minimizes potential downtime that would otherwise occur while waiting for parts delivery.

For maintenance departments, the 8-pack simplifies inventory management by providing a standardized set of replacement components. The consistent quality across all bearings in the pack eliminates concerns about performance variations that might occur when sourcing bearings from different suppliers or manufacturing batches.

This configuration is particularly valuable for facilities operating multiple forklifts that require regular maintenance. The ability to service several machines from a single purchase streamlines the maintenance process and ensures operational continuity.

Amazon’s free shipping option, with delivery between July 3-8, adds further value to the overall proposition. This cost saving, combined with the convenience of direct delivery, enhances the total package value beyond the bearings themselves.

Installation and Maintenance Guidelines

Proper installation of the MG307-2RS-1 bearings requires attention to detail to ensure optimal performance. The process typically begins with careful removal of the old bearings, preferably using a bearing puller to avoid damage to the mast components or bearing seats.

Required tools for proper bearing replacement include:

- Bearing puller

- Press tool or arbor press

- Cleaning solvents

- Torque wrench

- Appropriate lubricant

When removing old bearings, inspect the bearing seats for damage or wear that might affect the installation of the new components. Clean all surfaces thoroughly to remove any residue or contaminants before installation.

Proper torque specifications must be followed when securing the bearings in place. Over-tightening can cause bearing deformation, while insufficient torque may lead to movement and premature failure. Consult the forklift manufacturer’s specifications for exact torque values.

A recommended maintenance schedule for these bearings typically includes:

- Visual inspection every 500 operating hours

- Checking for unusual noise or vibration weekly

- Complete bearing assessment during annual forklift maintenance

- Lubrication verification according to equipment specifications

Warning signs that indicate bearing wear or failure include unusual noise during operation, visible wobble in the mast assembly, rough movement during lifting or lowering, and visible damage to the seals. Early detection of these issues can prevent more costly repairs.

To extend bearing life, maintain proper lubrication according to manufacturer recommendations, and ensure operating environments are as clean as possible. Avoid shock loading the forklift beyond rated capacities, as this can transfer damaging force to the bearings.

Smart Investment for Long-Term Equipment Reliability

The [8-Pack] MG307-2RS-1 Mast Guide Ball Bearing represents more than just a replacement part—it’s a strategic investment in your equipment’s performance and longevity. At $258.70 with free delivery, this package delivers exceptional value considering the critical role these bearings play in forklift operations. The precision engineering, impressive load ratings, and protective sealing make these bearings particularly well-suited for demanding industrial environments where equipment reliability directly impacts productivity. By choosing QJZ’s quality bearings, you’re not just fixing a problem—you’re preventing future issues and optimizing your material handling equipment for years to come.