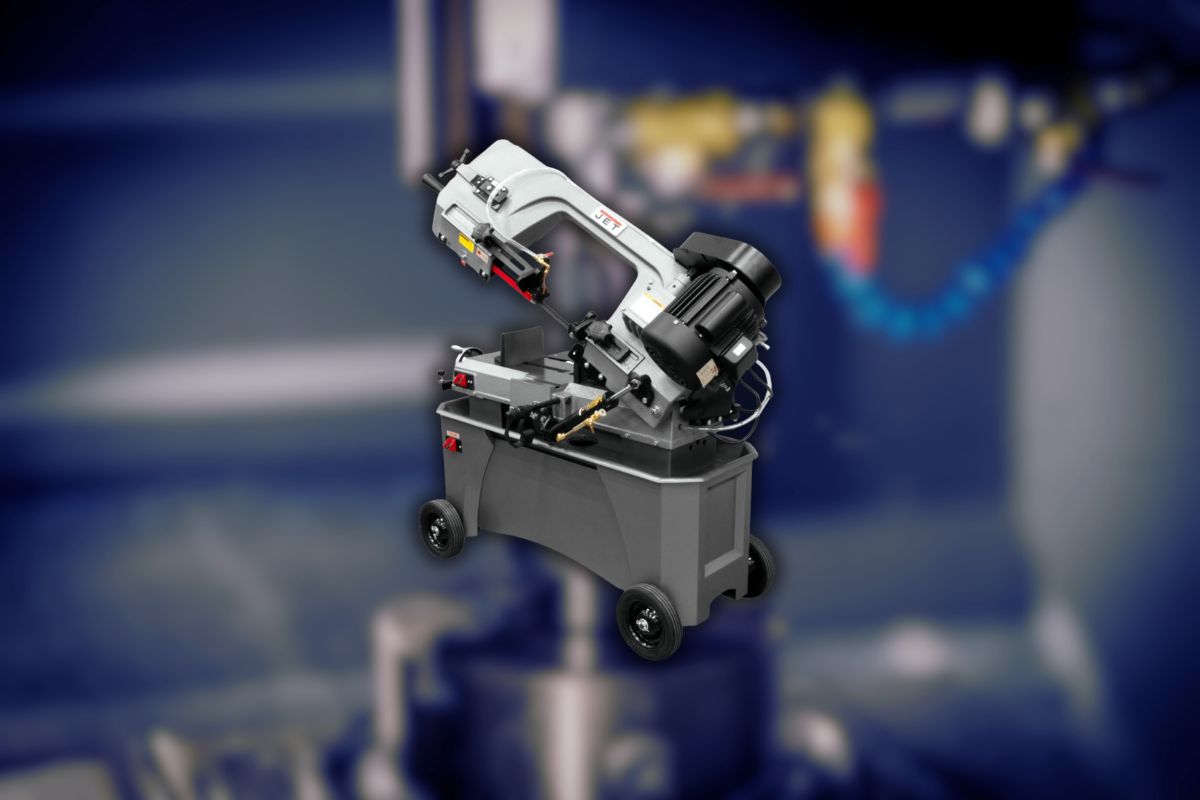

The workshop challenge: finding a reliable metal-cutting bandsaw that delivers precision without breaking down. “The Jet Band Saw has little to no vibrations… Very quiet and smooth running” – actual user testimonial highlighting the quality difference. Overview of what makes the JET 7×12 Deluxe Horizontal/Vertical Bandsaw stand out in a crowded market. Quick snapshot of the $2,059 investment and why it’s worth considering for both professionals and serious hobbyists.

Versatility That Transforms Your Workshop

The HVBS-712D’s signature feature is its ability to switch between horizontal and vertical cutting positions. The conversion process requires minimal effort—simply unlock the saw head, rotate it to a vertical position, and secure it in place. Horizontal mode excels at straight cuts through metal stock, while vertical mode enables intricate curve cutting and pattern work that would be impossible otherwise.

The Large Infeed Table Advantage

With its substantial 9″×12″ infeed table, the JET bandsaw provides exceptional workpiece support during vertical operations. This generous surface area stabilizes larger materials, dramatically improving both safety and cutting precision compared to smaller tables found on competitor models.

Materials Handling Capabilities

The HVBS-712D confidently processes:

- Structural steel and iron components

- Aluminum profiles and extrusions

- Brass and copper stock

- Nonferrous metals with appropriate blade selection

- Plastic materials, when using specialized blades

This versatility eliminates the need for multiple specialized cutting tools in your workshop.

Single vs. Dual-Orientation Comparison

Single-orientation bandsaws limit operations to either straight stock cutting or detail work—never both. This forces workshops to purchase multiple machines or accept workflow limitations. The HVBS-712D eliminates this compromise, providing complete metal-cutting functionality in one unit.

Space Optimization

Despite its robust capabilities, the JET bandsaw maintains a reasonable 48″×17″ footprint. The dual-orientation design effectively replaces two separate machines, conserving valuable floor space while maximizing metalworking capabilities, particularly beneficial for home workshops and smaller commercial operations.

Engineering Excellence: Build Quality & Performance Features

The cast-iron blade wheels represent a significant engineering advantage. Their substantial mass dampens vibration, resulting in smoother blade travel and more precise cuts compared to sheet metal wheels found on budget models. This translates to superior finish quality and reduced operator fatigue during extended use.

Motor Power Analysis

The ¾ HP motor delivers consistent torque throughout cutting operations. This power rating hits the sweet spot for metalworking—sufficient force for cutting structural materials without the excessive power consumption of industrial models. The 115/230V compatibility ensures flexibility for both home workshops and commercial settings.

Speed Settings for Material Optimization

Multiple blade speed settings allow operators to match cutting parameters precisely to material properties:

- Lower speeds for harder materials and stainless steel

- Medium speeds for structural steel and standard alloys

- Higher speeds for aluminum, brass, and nonferrous metals

This versatility optimizes both cut quality and blade longevity across diverse applications.

Coolant System Benefits

The integrated coolant system circulates cutting fluid to the blade-material interface, providing three critical advantages:

- Heat reduction at the cutting point, preventing work hardening

- Lubrication that extends blade life significantly

- Chip clearing that improves surface finish quality

These benefits become particularly evident during continuous production cutting.

Noise Performance

User reports consistently highlight the saw’s “quiet and smooth running” characteristics. The cast-iron construction absorbs operational vibrations that typically generate noise in lighter-duty models, resulting in a workshop-friendly sound profile that doesn’t dominate the environment.

Stability Factors

At approximately 374 pounds, the HVBS-712D provides the mass necessary for vibration-free operation. This weight, combined with the well-engineered base, creates a stable cutting platform that resists movement during operation—a critical factor in achieving precision cuts consistently.

Precision Cutting Capabilities & Workflow Efficiency

The quick-lock vise eliminates time-consuming adjustments between cuts. Operators can release, reposition, and secure workpieces in seconds without hunting for wrenches or keys. This seemingly simple feature dramatically improves workflow efficiency during production runs or repetitive cutting operations.

Preset Angle Capabilities

Built-in angle stops at 15°, 30°, and 45° streamline miter cutting operations. These preset positions ensure consistent angle reproduction without manual measurement, particularly valuable when fabricating multiple identical components for frameworks or assemblies.

Understanding Cutting Capacity

The “7×12” specification defines the maximum material dimensions the saw can process:

- 7″ vertical height capacity

- 12″ horizontal width capacity

- Round stock up to 7″ diameter

- Rectangle stock up to 7″×12″

These capacities accommodate most standard metalworking requirements outside heavy industrial applications.

Blade Control Systems

Precision blade tracking adjustments and tension control mechanisms ensure optimal blade positioning and appropriate tension for different materials. These fine-tuning capabilities directly impact cut accuracy and blade longevity, allowing operators to optimize performance for specific applications.

Real-World Applications

The versatility of the HVBS-712D makes it suitable for diverse metalworking tasks:

- Structural steel fabrication for frames and supports

- Precision cutting of thin-wall tubing for furniture and fixtures

- Aluminum profile trimming for custom assemblies

- Pattern cutting for decorative metalwork

- Production cutting of stock materials to length

Workshop Integration: Mobility, Storage & Setup

The four 8″ rubber wheels transform what would otherwise be a permanently positioned machine into a mobile workshop asset. These substantial wheels roll smoothly over shop floor imperfections while absorbing vibration during operation when the saw is positioned. The wheels include locking mechanisms to secure the unit during use.

Storage Capacity

The under-stand storage area provides organized space for:

- Extra blades and consumables

- Specialized jigs and fixtures

- Maintenance tools and supplies

- Coolant and lubricants

This integrated storage eliminates the need for separate storage solutions and keeps essential accessories immediately accessible.

Chip Management

The chip tray design collects metal shavings during operation, preventing shop floor contamination. Regular emptying of this tray requires minimal effort but significantly reduces cleanup time and improves shop safety by preventing slip hazards from metal chips.

Setup Requirements

The bandsaw requires:

- Standard 115V power with 15A circuit capacity (or 230V option)

- Approximately 60″×40″ operating space to accommodate the saw plus material handling

- Initial assembly of the stand and coolant system (approximately 1-2 hours)

- Level flooring for optimal performance

Safety Certification

The CSA/CUS certification verifies compliance with North American safety standards. This certification often satisfies insurance requirements for commercial workshops and provides assurance of electrical safety and operational standards compliance for all users.

Purchase Considerations & Amazon Advantages

At $2,059, the HVBS-712D positions in the mid-range of the market:

- Approximately 15-20% higher than entry-level horizontal/vertical bandsaws

- 25-30% lower than premium industrial models with similar capacities

- Competitively priced when factoring included features like the coolant system and mobile base

The cost reflects its positioning as a prosumer-level tool with commercial-grade capabilities.

Return Policy Specifics

Amazon’s 30-day return policy for this heavy machinery includes:

- Full refund eligibility for defective or damaged units

- Return shipping arrangements for this oversized item

- Straightforward documentation process through the Amazon return center

- Resolution options that include replacement or refund

This policy provides significant buyer protection for this substantial purchase.

Delivery Expectations

The scheduled delivery options feature:

- Date and time window selection during checkout

- Curbside delivery is standard, with in-shop placement available

- Real-time tracking through the Amazon system

- Pre-delivery communication from the carrier

- Packaging designed for protection during transport

Technical Support Access

Amazon provides multiple customer support channels for equipment questions:

- Direct phone support seven days a week

- Live chat with specialized heavy equipment representatives

- Email support with a 24-hour response commitment

- Connection to the manufacturer support when needed for technical specifics

Warranty Coverage

The manufacturer’s warranty includes:

- Parts coverage for mechanical components

- Motor and electrical system protection

- Exclusions for consumable items like blades and coolant

- Registration requirements for warranty validation

- Service center network for covered repairs

The Smart Investment for Your Workshop

The JET HVBS-712D represents more than just another tool purchase—it’s a workshop upgrade that transforms your cutting capabilities. At $2,059 on Amazon, you’re investing in German-engineered precision that consistently delivers clean, accurate cuts while offering the versatility to handle virtually any metalworking project. The included coolant system, mobility features, and robust construction ensure this bandsaw will remain a workshop centerpiece for years to come. For serious metalworkers who value precision and reliability, the decision becomes clear: the JET HVBS-712D delivers professional results that justify every dollar of its investment.